Print paper boxes on demand at Tan Phat

In today's fiercely competitive era, a beautifully designed and printed paper box can be the deciding factor in helping a product stand out on the shelf and attract the attention of consumers. In addition, printing paper boxes on demand also helps businesses save costs and optimize the process of packaging and transporting products. Let's join Tan Phat Printing to clarify the service of printing paper boxes on demand and get suggestions to get a standard printed box that is suitable for your business!

Information you need to know about printing paper boxes

What is paper box printing?

Paper box printing is the process of creating packaging products from paper or cardboard, including designing, printing and processing to create boxes with shapes and sizes suitable for the products to be packaged. This process is not simply printing information on the paper surface, but also includes many complex steps such as cutting, folding, gluing and shaping to create the final product.

The outstanding feature of paper box printing is the high customization ability, allowing businesses to create unique packaging products, suitable for their brand and products. From the choice of paper material, size, shape to color and decorative motifs, all can be adjusted according to the specific requirements of customers.

What role do paper boxes play in business and marketing?

Paper boxes play an important role in the business and marketing strategies of many businesses. Not only a means of protecting products, paper boxes are also an effective communication tool, contributing to creating brand image and increasing product value.

Paper boxes as an effective marketing tool

In today's competitive business world, paper boxes have gone beyond the mere function of packaging products. They have become an indispensable part of a business's overall marketing strategy. A beautifully designed and unique paper box can attract customers' attention at first sight, creating a strong and different impression compared to similar products on the shelves.

Custom printed paper boxes allow businesses to customize the design, color, and message on the packaging, effectively conveying the brand value and outstanding features of the product. This not only helps increase brand recognition but also creates an enjoyable shopping experience for customers, contributing to increasing the perceived value of the product.

The impact of paper boxes on customers' purchasing decisions

Research has shown that product packaging, including paper boxes, has a significant impact on consumers' purchasing decisions. A professionally designed and eye-catching paper box can create a positive impression of the quality and value of the product inside, thereby promoting purchasing decisions.

Paper boxes also play an important role in providing product information. Through design elements such as color, images and printed content on the box, customers can quickly grasp the features, uses and benefits of the product. This not only saves time for buyers but also increases the likelihood that they will choose your product instead of your competitors.

The role of paper boxes in branding

Paper boxes are an important part of the process of building and developing a brand. By consistently using brand identity elements such as logos, colors, and design styles on paper boxes, businesses can increase brand memorability and association in the minds of customers.

In addition, the quality of the paper box also reflects the quality and value of the brand. A paper box that is printed delicately and uses high-quality materials will create the impression of a professional and trustworthy brand. Conversely, a poor quality paper box can reduce the perceived value of the product and negatively affect the brand image.

Popular paper box designs and qualities

In the printing and packaging industry, choosing the right style and quality of paper boxes plays a vital role in creating a final product that meets the customer's requirements. This section will delve into the key aspects of paper boxes, including material, style and size.

Paper box printing material

The material used to print paper boxes is the deciding factor in the quality, durability and aesthetics of the final product. Each type of material has its own characteristics, suitable for different purposes. Below are some common materials used in print paper boxes on request:

1. Ivory paper

Ivory paper is a high-quality paper with a smooth white surface and high hardness. The outstanding feature of Ivory paper is its ability to reproduce colors well, creating sharp and vivid printed images. This type of paper is often used to print boxes for cosmetics, high-end foods or products that need to show luxury.

Advantages of Ivory paper:

- High whiteness, smooth surface

- Excellent color reproduction

- Good stiffness, suitable for complex box designs

However, Ivory paper is also more expensive than other common types of paper.

2. Duplex paper

Duplex paper is a two-sided paper, one side is white and the other side is gray or brown. This is a popular choice for paper boxes that need good stiffness but do not require high aesthetics on both sides. Duplex paper is often used to make shoe boxes, gift boxes, or regular packaging boxes.

Characteristics of Duplex paper:

- Good hardness, good bearing capacity

- Reasonable price

- Can print beautifully on white surface

However, the back of Duplex paper is not suitable for high quality printing.

3. Couche paper

Couche paper is a type of paper with a surface coated with a special material, which helps increase smoothness and ink absorption. This is the ideal choice for paper boxes that need to print high-quality images and vivid colors.

Advantages of Couche paper:

- Extremely smooth surface, ideal for high quality offset printing

- Excellent color and detail reproduction

- Suitable for many post-printing techniques such as hot stamping and lamination

Couche paper is often used for high-end cosmetic boxes, gift boxes, or products that need to show luxury and sophistication.

4. Kraft paper

Kraft paper is characterized by its durability and biodegradability, which makes it an ideal choice for businesses looking to demonstrate their commitment to environmental protection.

Advantage:

- Brings natural beauty with rustic, modern colors, suitable for many types of products.

- Supported by customers for environmental protection

However, because the paper surface is not coated or the ink absorption level is not high, when printing on Kraft paper, the colors may be less prominent than other types of paper. This is something to consider when designing to ensure the image and message are conveyed most effectively.

5. Crystal Paper

Crystal paper has a glossy, smooth surface, high hardness, and bright white color. The paper is often coated with a thin film to increase gloss and durability.

Advantage:

- High quality printing, vivid colors.

- High stiffness helps the paper box have a stable shape.

- Beautiful, luxurious glossy surface.

Disadvantages:

- The price is relatively high compared to other types of paper.

Often used to print cosmetic boxes, high-end food boxes, gift boxes, phone boxes, etc.

6. Bristol paper

Bristol paper has high stiffness, flat, smooth surface, bright white color. Paper has various thicknesses, from thin to thick.

Advantage:

- Good print quality, sharp colors.

- High stiffness, helps paper boxes to be durable.

- Flat surface, easy to process.

Disadvantages:

- Less color variety than other types of paper.

Often used to print gift boxes, technology product boxes, labels, business cards, etc.

7. Metalized Paper

Metalized paper is a type of paper with a thin layer of metal coating on the surface, creating a metallic, sparkling effect.

Advantage:

- Increase the aesthetics and luxury of the product.

- Easy to print, create special effects.

Disadvantages:

- High cost.

- Cannot withstand high temperatures.

Often used to print wine boxes, high-end cosmetic boxes, fashion product packaging, etc.

8.Carton (Wave, Cold,...)

Carton is a type of paper with many layers, including corrugated layers and cardboard layers. Depending on the number of corrugated layers and the thickness of the paper, there are different types of carton.

Advantage:

- High hardness, good bearing capacity.

- Good protection of the product inside.

- Low cost.

Disadvantages:

- The surface is not as smooth as other types of paper.

Often used to make boxes for heavy products such as electronics, household appliances, food, etc.

Paper box design

The design of the paper box also plays an important role in the consumer experience. A beautiful, unique box not only attracts the eye but also contributes to conveying the brand story and the value of the product inside.

Square and rectangular boxes

The two most popular shapes are square and rectangular boxes. This design style shows simplicity but no less elegant, suitable for most types of products such as cosmetics, gifts or food. Rectangular boxes are often used for larger products, creating a feeling of fullness and solidity.

Despite the simple shape, designers can still vary them with design elements such as color, pattern, and material to increase appeal. Moreover, consistency in box design will help strengthen the brand and memorability in the minds of customers.

Polygonal and hexagonal boxes

Polygonal and hexagonal boxes are creative choices that not only attract attention but also leave a strong impression on customers. This style is often applied to special products such as tea, bird's nest or moon cakes, creating a unique and luxurious feeling.

The strength of these types of boxes is the high customization in design. Designers can play with height, proportions and between decorative elements to enhance the aesthetic value of the product. Using polygonal boxes can increase brand recognition and positive customer feelings towards the products.

Box type with attached lid and removable lid

Boxes with fixed lids and removable lids are also two popular models in the packaging industry. Boxes with fixed lids provide convenience and good protection for the products inside because they do not need to be opened for inspection. Meanwhile, removable lid boxes provide comfort and ease in disassembly, as well as reuse later.

While removable lid boxes often bring a more elegant feel, solid lid boxes show the certainty and safety of the product during transportation. Usually, which box model should be used depends on the type of product and the needs of the consumer.

Paper box printing size

The size of the paper box not only affects the appearance of the product but is also closely related to the marketing strategy, presentation method, and especially the customer experience when using the product.

The service of printing paper boxes on demand helps businesses easily customize the box size to suit their needs while still maintaining aesthetics. The initiative in choosing the size will create unexpected experiences for consumers and significantly increase brand value.

At Tan Phat Printing, we can print any size that customers need.

If you do not know which size to print paper boxes, let Tan Phat Printing advise you thoroughly to get the most satisfactory box model, highlighting the product and brand.

The best paper box printing technology and techniques today

Paper box printing techniques

1. Foil stamping of paper packaging

Foil stamping is a technique that creates metallic, shimmering effects on paper surfaces by pressing a thin layer of metal onto the printing surface.

- Principle: A thin layer of metal-coated film (such as gold, silver, copper, etc.) is pressed onto a printing surface that has been coated with a special glue.

- Advantage: Increase the aesthetics and luxury of the product, creating a highlight.

- Application: Often used for high-end paper boxes, gift boxes, cosmetic boxes

2. Matte and glossy lamination for paper boxes

Lamination is the process of covering a thin film layer on the printed surface to protect and increase the aesthetics of the product.

- Matte lamination: Creates a smooth, matte surface that is resistant to fingerprints and scratches.

- Glossy lamination: Creates a glossy, bright surface that highlights images and colors.

- Advantage: Increased durability, waterproof, scratch resistant, protects printed colors.

- Application: Lamination is widely used for paper boxes and product packaging.

3. Embossing, debossing

Debossing and embossing are techniques of creating raised or depressed images or letters on the surface of paper using a die.

- Embossing: Creates images that are recessed into the paper surface, giving it a luxurious, classic feel.

- Embossing: Create raised images on the paper surface, creating a striking highlight.

- Advantage: Increase aesthetics, create 3D effects, make products unique.

- Application: Often used for high-end paper boxes, invitations, gift boxes.

4. UV coating on packaging

UV coating is the process of shining ultraviolet light onto a printing surface that has been coated with a layer of UV ink.

- Advantage: Increase gloss, color fastness, scratch resistance, dirt resistance.

- Application: Often used for parts that need to be highlighted such as logos, text, images

5. Creasing and die-cutting in packaging printing

Die cutting is the process of cutting, folding and shaping printed products.

- Principle: Use a die cutter to create grooves, folds and cuts according to the design.

- Advantage: Helps products have complete shape, easy to pack and transport.

- Application: Used in all paper box manufacturing processes.

Comparison table of paper box printing techniques

|

Technique |

Describe |

Main advantages |

Main disadvantages |

Popular applications |

|

Hot stamping |

Press a thin layer of metal onto the surface |

Increase aesthetics and luxury |

High cost |

High-class paper box, gift box |

|

Laminating |

Cover with a thin protective film |

Increased durability, waterproof, scratch resistant |

May reduce ink adhesion (if laminated too thick) |

Most types of paper boxes |

|

Embossing/Debossing |

3D surface modeling |

Increase aesthetics and uniqueness |

High cost, need stamping mold |

High-class paper boxes, invitation cards |

|

UV coating |

UV light on the surface |

Increase gloss and color fastness |

Higher cost than non-UV coated |

Logos, letters, and images need to stand out |

|

Closed |

Cut, fold, and shape boxes |

Complete product, easy to pack |

Requires specialized machinery |

All kinds of paper boxes |

Paper box printing technology

1. Offset Printing

- Principle: The ink is transferred from the metal plate through a rubber blanket and then printed onto the material.

- Advantage: High image quality, vivid colors, good color fastness, suitable for many types of paper and surfaces.

- Disadvantages: High initial setup cost, relatively long production time, not suitable for small quantity orders.

- Application: Printing high-quality paper boxes, magazines, books, and product packaging requires high quality.

2. Flexo Printing

- Principle: The ink is transferred directly from the rubber printing plate onto the material.

- Advantage: Fast printing speed, low cost, flexible, suitable for many types of materials.

- Disadvantages: Image quality may not be as sharp as offset printing, not suitable for overly complex designs.

- Application: Print paper bags, food packaging, labels, paper boxes in large quantities.

3. Digital Printing

- Principle: Images are transferred directly from the design file to the printer.

- Advantage: No need to print, fast printing, flexible, can print small quantities, good image quality.

- Disadvantages: The cost of printing each product is higher than offset and flexo printing, and the ink can fade over time if not properly maintained.

- Application: Proof printing, sample printing, small quantity printing, variant printing.

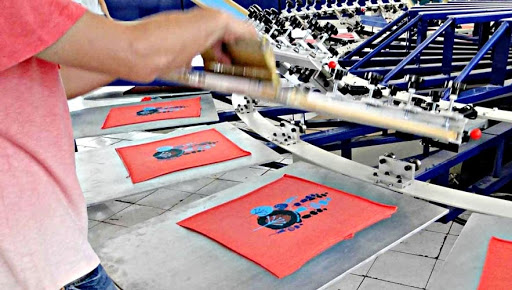

4. Screen Printing

- Principle: The ink is pushed through a mesh screen with tiny holes to create the image on the material.

- Advantage: Can be printed on many different materials (including fabric), thick ink, good adhesion, suitable for printing on curved surfaces.

- Disadvantages: Slow printing speed, high cost, not suitable for large quantity printing.

- Application: Print on fabric, wood, plastic, glass, and some special papers.

5. Gravure

- Principle: The ink is contained in recessed cells on a copper cylinder and transferred to the surface of the material.

- Advantage: Very fast printing speed, suitable for large quantity printing, good image quality, especially continuous images.

- Disadvantages: High equipment costs, high print production costs.

- Application: Print soft packaging, newspapers, magazines with many images.

Summary comparison table of printing technology

|

Technology |

Main advantages |

Main disadvantages |

Popular applications |

|

Offset |

High quality, variety |

High cost, long time |

High-quality paper boxes, magazines, books |

|

Flexo |

High speed, low cost |

Lower quality than offset |

Paper bags, food packaging |

|

Digital |

Flexible, low quantity printing |

Higher cost/product |

Test print, sample print |

|

Silk |

Print on many materials, thick ink |

Slow speed, high cost |

Print on fabric, wood, plastic |

|

Copper pipe |

High speed, continuous image |

High equipment costs |

Soft packaging, newspaper |

Beautiful paper box models are printed a lot at Tan Phat

Diverse designs, diverse industries, rest assured when printing paper boxes at Tan Phat:

Cosmetic box

Gift boxes

Food carton boxes

Moon cake box

Fashion box

Jewelry box

Agricultural produce box

Paper box printing service on demand at Tan Phat Printing

Providing custom paper box printing services, Tan Phat Printing not only provides quality products but also meets all the specific needs of customers. We understand that each business has its own unique requirements and we are ready to support you in every process, from design to completion.

Print paper boxes on demand at cheap prices

Tan Phat Printing's low-cost custom paper box printing service ensures high-quality products at reasonable prices, helping you optimize costs while still ensuring promotional effectiveness.

Print paper boxes on demand in small quantities

We provide custom paper box printing service in small quantities, especially suitable for small businesses or events that need urgent printing.

Print paper boxes on demand quickly, get it the same day

With a professional production process, Tan Phat Printing provides super fast custom paper box printing service, helping you receive paper bags the same day while still ensuring quality.

Print paper boxes on demand in large quantities

We print paper boxes on demand in large quantities at preferential prices. This is the perfect solution for businesses that need to print packaging in bulk at a budget-friendly price.

Paper box printing process is fast, neat, and economical at Tan Phat Printing

Tan Phat's paper box printing process is optimally designed to save you time and money. With the combination of modern technology and dedicated staff, you can rest assured about the final product we provide. Each printing stage is carefully checked to ensure that you receive the most perfect product.

Tan Phat Printing has a very simple and quick process for ordering custom printed paper boxes:

- Step 1: Contact us via website, phone or email to provide information about your printing needs.

- Step 2: Get design advice from our professional team, helping you get the right printed paper box product at competitive prices.

- Step 3: Confirm the design, we proceed to production and deliver on time.

Why should you choose to print paper boxes on demand at Tan Phat Printing?

Tan Phat Printing is proud to be a pioneer in the field of packaging printing, especially paper box printing. With extensive experience and modern machinery systems, we are committed to providing customers with high-quality paper box products, meeting all requirements in terms of design and quantity.

Benefits of choosing to print paper boxes at Tan Phat Printing

- Unique, impressive design: Our experienced design team will help you create unique paper box designs that clearly express your brand style and message.

- Sharp print quality, true colors: Thanks to the application of modern offset printing technology, the images on your paper boxes will be reproduced in the most vivid and realistic way.

- Various materials and sizes: We provide many types of high quality paper such as couche paper, kraft paper, art paper... with various sizes, helping you choose the right one for your product.

- Exquisite workmanship: Processing techniques such as hot stamping, embossing, lamination… will help your paper box become more luxurious and attractive.

- Competitive prices: We are committed to providing customers with the most competitive prices on the market, along with many attractive incentive programs.

- Fast delivery: We always ensure production progress and on-time delivery, helping you avoid interruptions in your business.

- Environmentally friendly: We use environmentally friendly inks and papers, contributing to protecting the living environment.

Tan Phat Printing commits to bring you high quality paper box products, meeting all customer requirements. Please contact us for detailed advice and quotation.

Frequently Asked Questions

We provide a complete custom box design service. Our creative design team will work directly with you to realize your ideas, creating a unique and impressive box design.

The production and printing time of the box depends on the quantity and special requirements of the customer. Normally, the production time is between 7 and 14 days. However, we also have express service if you need it urgently.

Yes, we offer small quantity box printing services, suitable for small businesses or special needs that do not require mass production.

Yes, we offer home delivery service to all our customers. Just place your order and we will handle all the delivery procedures for you.

We are always ready to provide sample paper box for customers. You can consider different designs before deciding on the desired one.

Printing paper boxes is an indispensable step in building a brand and enhancing product value. Choosing the right material, style and size of the box will create a deep impression on customers. With the continuous development of printing technology, Tan Phat Printing is proud to bring quality paper products and professional services, effectively meeting your needs.

Contact Tan Phat printing now for advice on designing beautiful, affordable, professional paper boxes.